Air-powered devices serve a key role in a range of commercial applications, turning pressurized air into mechanical motion to manage doors, entrances, and various equipment. Their ability to provide effortless and optimal operation makes them an excellent choice for numerous automated systems. However, there are cases where human intervention becomes necessary, leading to the innovative design of pneumatic actuators with human intervention capabilities.

These specialized actuators not just utilize the power of compressed air but also allow technicians to control manually the device when needed. This capability is particularly beneficial in crisis situations or during repair, making sure that systems can be effectively operated even when pneumatic power is compromised. Grasping the operation and benefits of pneumatic actuators with manual override enhances their application flexibility, making them crucial in providing smooth operational effectiveness across different industries.

Grasping Pneumatic Actuators

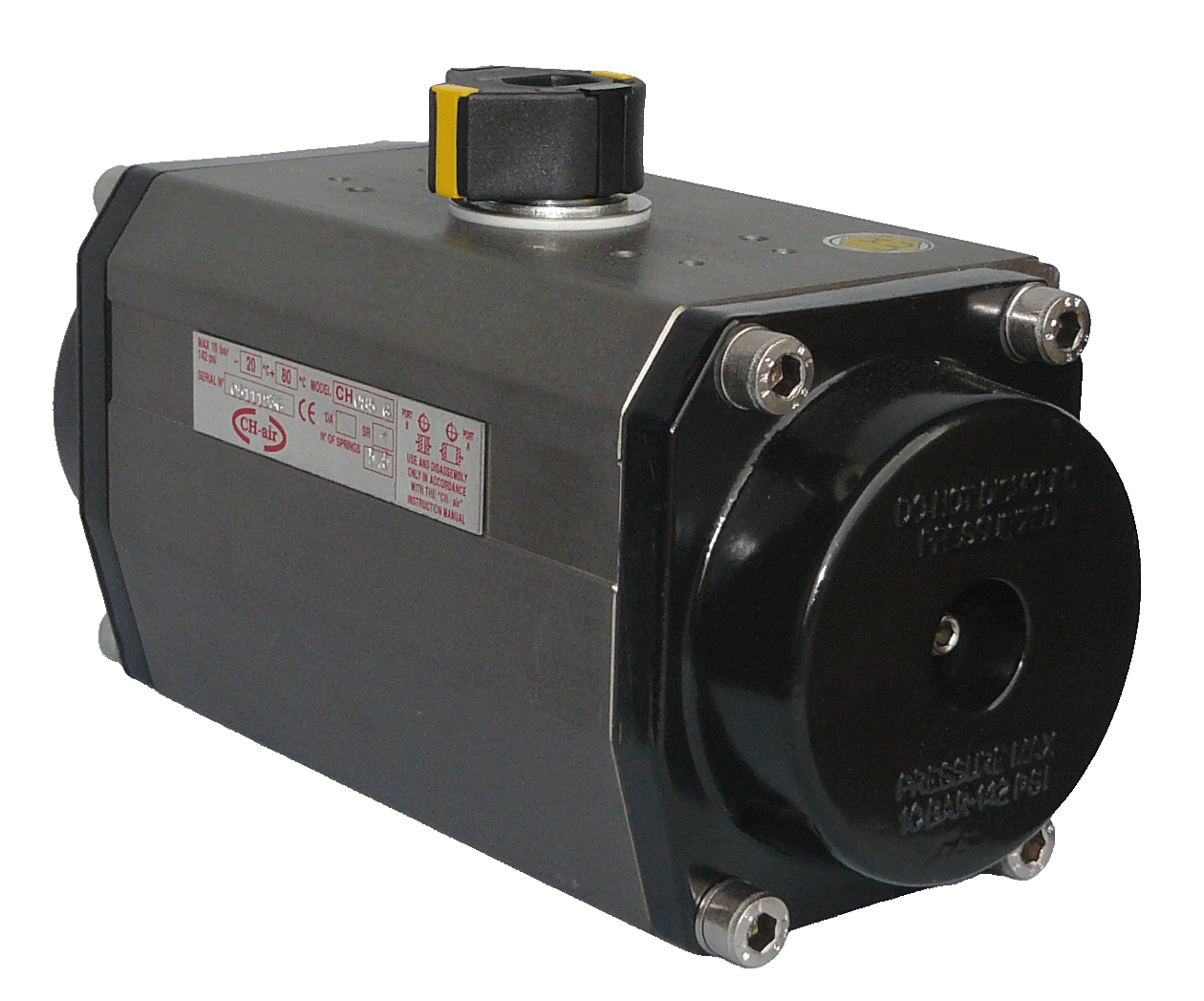

Compressed air actuators are devices that use pressurized air to change force into motion, generally resulting in linear or circular motion. These actuators are frequently used in diverse industrial applications due to their quickness, dependability, and capacity to produce considerable strength. The mechanism relies on the growth of air within a chamber, pushing a rod to generate movement. This technology plays a important role in automated processes, management systems, and machinery operations.

One of the key features of pneumatic actuators is their straightforwardness and efficiency. They are fairly easy to install and service, which makes them an attractive option for numerous industries. Additionally, pneumatic systems can work in risky environments, as they do not require electrical parts that could pose a hazard of fire. This makes them appropriate for applications in industries such as production, food manufacturing, and chemical processing.

A pneumatic actuator with manual override incorporates a system that allows for manual control in case of an crisis or power failure. This feature ensures that operators can directly adjust the actuator’s setting without depending solely on the pneumatic system. Manual override capabilities enhance safety and flexibility, allowing for ongoing work or upkeep without complete dependence on automated systems.

The Significance of Manual Control

Human override capabilities in pneumatic actuators are essential for guaranteeing operational consistency, particularly in situations where automation breaks down or requires human intervention. In sectors that require precise control, such as production or power production, the option to manually adjust a pneumatic actuator can mitigate costly pauses and maintain safety measures. This alternative allows operators to bypass automated systems and regain command over machinery and processes when needed.

Additionally, manual overrides empower operators with improved safety measures. In critical moments, where an automated system may break down or respond poorly, the manual override function can facilitate quick decision-making and immediate action. This functionality is crucial for addressing unforeseen circumstances, such as equipment jams or power outages, ensuring that personnel can respond swiftly without being fully dependent on automated controls.

Finally, including manual override functions into pneumatic actuators provides greater flexibility in operations. It enables maintenance personnel to diagnose issues directly, test equipment functionality without impacting the overall process, and modify the settings of pneumatic actuators based on real-time conditions. This flexibility is crucial for maximizing productivity while minimizing the risk of incidents that could arise from total reliance on automation.

Uses and Gains

Compressed air actuators with hand override capabilities are essential in multiple industries, especially in mechanized environments where consistency is important. air/manual actuator combo are frequently used in manufacturing and process control systems, where they enable the operation of valves and other equipment. In scenarios where automated systems may fail or require maintenance, the manual override feature allows operators to retain control, ensuring that processes can proceed without interruption.

Another significant utilization is in safety-critical systems. In industries like oil and gas, chemical processing, or water treatment, the ability to manually override a pneumatic actuator provides a key safety mechanism. In the event of an crisis or system failure, operators can quickly engage the manual override, efficiently diminishing risks and preventing incidents. This twofold control capability enhances overall system reliability and safety.

Moreover, pneumatic actuators with hand override contribute to boosted operational efficiency. By allowing for quick manual control, they minimize downtime during maintenance or sudden system alarms. Operators can easily switch to manual mode to troubleshoot or adjust system settings without considerable delays. This flexibility not only enhances efficiency but also offers peace of mind to operators, knowing they have a dependable backup method at their disposal.